When we think about a day aboard, we are often whisked back to pleasant breezes, good times, shared stories and meals in the cockpit. For the racer in us, it might be remembering that hard beat to the weather mark. It isn't often we consider times spent on routine and preventative maintenance, or exploring the dark innards of our boats.

We should take some time to consider these dark and out of the way areas. They contain the guts of systems that keep our boats afloat. They help get us out and back safely from our voyages, be they day sails or circumnavigations.

Lift up an access board below your seat cushions and you may find something rather surprising, or frightening, depending on the state of maintenance or general disuse.

|

| | Did someone hook up a garden hose inside this boat? We almost lost a fellow Catalina owner during a fleet whale watching cruise in Monterey Bay. His pipe nipple "through hull" failed when the glue bond released the nipple. If we had been sailing farther offshore it would have ended in a rescue. | |

Through hulls are present on most Catalinas. They provide a means for getting water on board for use in the head and for engine cooling; for sink drains, and even discharging your holding tanks if you are far enough off shore.

Early standards for fiberglass boat building were few and far between. Most builders were working with materials and tools for wooden boat building, often borrowing techniques from other industries while coming up with their own new practices where none existed before.

Early pipe nipple "through hulls" are an example. Originally intended to be threaded into an undersized hole drilled in the fiberglass hull, more often than not they are now only held in place by the tenuous bond between the polyester resin and bronze nipple. The layers of fiberglass built up inside of the hull around the nipple became known as the "volcano". The pipe nipple is simply flush with the outside of the hull and so gains no additional support there.

| The threaded nipple and layers of fiberglass form the "volcano" shape on early through hull installations. An impact event to the valve or attached hoses can have you scrambling if this precarious bond breaks. Owners have reported being suprised when the nipple easily came out of the hull when they attempting to replace the valve. |

|

Without any support for the nipple on the outside of the hull, movement of any items stored in the compartment or a tug on a hose can lead to forces and loads that can break the bond between the nipple and the hull.

In the Monterey Bay case, an unknown combination of factors caused the pipe nipple "through hull" to spring a leak. It was only timing that prevented to boat from sinking when the owner awoke in the middle of the night to discover eight inches of water above the cabin sole.

By early 1983 newer style through hull fittings incorporating a large flange on the outside of the hull and a large flange nut inside were introduced. This style was a major improvement over the original threaded-in nipples. With the fitting securely clamped into the hull, a much larger force is required to cause a failure. For this reason, any marine surveyor seeing the original style "through hulls", will and should insist that they be replaced.

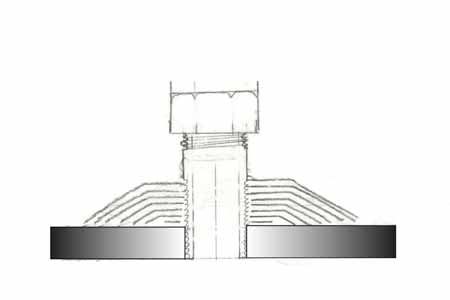

|

| Note the flange nut on the inside of the hull along with the corresponding flange on the outside of the hull to create additional support. Caution! If you have a pre 1983 boat with a post 1983 ball valve, check for a through hull flange nut below the valve, indicating both the valve and through hull have been replaced. A few unscrupulous owners, when preparing a boat for sale, have replaced only the valve, hoping to save money while fooling the buyer's surveyor. |

Fast forward another decade to late 1993. Another improvement to the through hull and valve design became available and was implemented by Catalina Yachts.

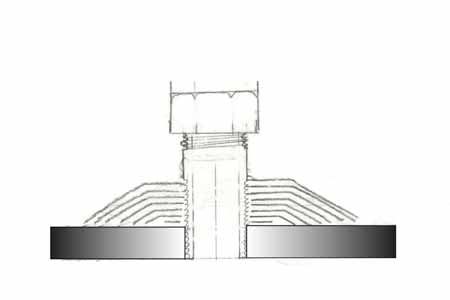

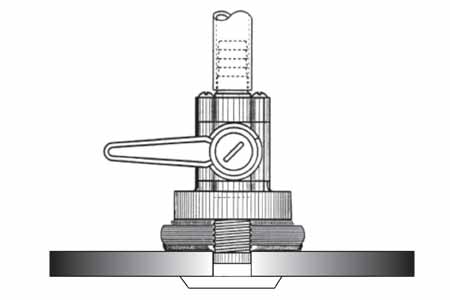

The newest design consists of a seacock that incorporates a large diameter buttressed flange directly onto the base of the valve body. The through hull screws directly into this large flange. It eliminates the flange nut and places the flange directly against the hull and backing block. It prevents a moment or force from making it to the portion that passes through the hull, the weakest link.

These newer designs are more difficult for the builder to inventory as there are many more combinations of valve size, hose size, straight or elbow, hose barb or female thread and number of outlets. Even with the added stocking challenges, the improvements in design, strength and safety they provide far outweigh the challenges.

| Current seacock design uses a large buttressed base bearing directly against a backing block. When compared to the earlier design above, it is easy to see how it is more stable and less likely to be broken off by a falling object inside a locker. Drawing depicts a single, straight barb configuration. Other configurations are available. |

|

Here are a few through hull guidelines to keep your boat afloat:

- Locate every through hull on your boat.

- Know the evolution/origin of your through hull fittings.

- Replace any first generation "through hull" pipe nipples with an improved version.

- Open and close them regularly, at least four times a year.

- Keep them lubricated with MareLube.

- Close through hulls when not in use.

- Close every through hull when leaving the boat.

- When you leave the boat, hang your engine ignition keys from the engine intake valve. You are unlikely to fry your engine if you have to retrieve the keys off of the valve.

Knowing the origin of your boat's through hull fittings will help ensure your boat doesn't become your early morning water alarm clock.

|

| An example of the current production seacocks installed on a recently produced Catalina, all set for offshore sailing. The black valve is mounted directly onto the white backing block. |

A few examples of the different types of valves are linked below.

Catalina Direct

Tech Support

Visit our tech support library at Help & Advice