You’ve just returned from a frustrating day of troubleshooting on your boat. The engine is overheating and you’re in a rotten mood. This article provides insight into places to check and suggests a new procedure to add to your boat maintenance routine. Both will help prevent cooling headaches going forward.

When your engine is cold the coolant should be a bit above the "ADD" line. When your engine is at operating temperature the coolant should be at or below the "MAX HOT" level.

Check for coolant level at the recovery tank

Most engines installed in Catalinas are equipped with "fresh water" cooling. Make sure your engine coolant recovery tank is topped off with a 50% mixture of anti-freeze and water. Check it again after running the engine up to temperature. If you have gotten air into the fresh water circuit, it will continue to work out and into the recovery tank for an extended period of time. Hours perhaps. When air comes out into the tank, coolant has taken its place and the level in the tank will drop.

Check water flow

When your engine overheats, check the transom exhaust outlet. If water expelled with the exhaust is less than normal, double check the raw water strainer. There’s always a strainer adjacent to the engine thru-hull intake. Don't assume it’s clean even if it appears to be. Close the valve and disassemble the strainer. Clean it thoroughly. Confirm the strainer element is in not damaged. You should always carry a spare aboard.

Next, it's time to confirm water is flowing freely past the thru-hull fitting and valve.

Be careful

• You serviced the valves at your last haul-out

• You open and close the valves regularly, preferably each time you go sailing

• You know that the valve opens and closes properly

Now, open the valve briefly. You should see a low pressure, but free flow of water out of the strainer. If not, you must check for blockage at the valve and thru-hull.

You can only check for and clear blockage from inside the boat if you have modern Marelon ball valves or Marelon seacocks. These valves open straight through when the handle is rotated 90 degrees. Remove the hose barb from the top of the valve. Slide a wooden dowel (whose outside diameter is approximately the diameter of the ID of the valve) down through the open valve to clear any marine growth or debris that may be restricting water flow below the valve, inside of the thru-hull fitting. Unfortunately, if you have an early boat with brass gate valves, there is no way to check for or clear blockage from inside the boat.

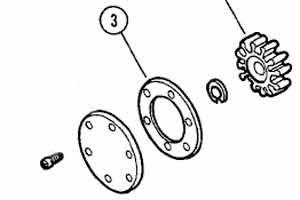

Check your raw water pump for broken vanes

From there you want to move to your raw water pump. Remove the pump cover and examine the impeller. If your impeller is missing any vanes, they have broken off and are lodged somewhere in the raw water circuit. You must find all of the small parts of the impeller. Find the pieces and rebuild your impeller like a puzzle. This will insure there are no small chunks lodged within the heat exchanger. Any stray rubber bits may restrict water flow and cooling. If the coolant tank, thru-hull, strainer, and impeller are in good shape, it might be time to consider flushing your heat exchanger, or is it?

Note the set that has formed in the old impeller on the left. The impeller vane is bent by the "Cam" shape inside the pump. After it passes the cam, the vane rebounds. It is only this combination of motion that pumps water. If the rubber is old and stiff or has taken a set, the vane won't rebound and the pump will not move water at the proper rate.

Check the age of the impeller

One of our staff, a fellow Catalina owner, had followed all of these steps and was still not satisfied with the results. A mechanic explained that looking for a broken impeller was not adequate. The impeller may look fine, but if it is simply old it probably won't pump properly. The vanes must flex easily to snap back after passing the cam. If it is old and slowly becomes straight again, the vane has already passed by the inlet and doesn't grab its share of new water.

A photo of a typical raw water pump with the cover plate removed. It is easy to see how the flat, or "cam" forces the vane over, constricting the volume of the space between the vanes, and forcing fluid out of the left side port. Left too long, the impeller will take a permanent set.

Add this to your fall winterizing check list

Impellers are also not meant to be left in a static engine for extended periods. Living in California we typically sail all year round. But if your boat isn't sailed during the winter, it's another story. Your winterizing procedure should include removal of of the raw water impeller. Some owners don't bother removing in the fall. They simply install their new spare each spring to start the season with a fresh impeller.

If your boat is laid up for the winter, or even if there are just extended periods of time when the engine will not be in use, consider adding a step to your buttoning down procedure: remove the raw water impeller and keep a spare on board.

Here's another nautical tip. If you remove the impeller, place it in a zip lock bag with your engine keys. It is a good way to guarantee you will remember to reinstall it before you head out next time.

Notice all of the small tubes inside of your heat exchanger. Both ends have caps that can be removed for maintenance

Check your heat exchanger

In your car, the radiator is exchanging the engine's heat from the coolant to the surrounding air. The heat is passed from one fluid (the coolant pumped by the water pump) to another fluid (air being "pumped" by the fan). In your boat, the heat exchanger takes the place of your car's radiator. It exchanges the heat in one fluid (the coolant pumped by the fresh water pump) to another fluid, the sea water (pumped by the sea or "raw" water pump).

If none of the above steps have solved the problem, the issue may be with your heat exchanger. If any of the tubes inside your heat exchanger are blocked, the cooling capacity of the heat exchanger is reduced. You may be able to clean the end chambers by hand. But to accomplish a thorough job of cleaning inside of the small tubes, engage the folks at your local radiator shop. Have them "boil out" your heat exchanger in the same way they might a radiator to remove any buildup of foreign material.

Just one more thing...

Diesel mechanics recommend bringing diesel engines to operating temperature at least once a month, and to run there, under load, for at least an hour. This procedure burns off any built up carbon deposits that can lead to loss of power and difficult starting.

If you question which impeller your engine requires, see Identifying Your Raw Water Pump.

Catalina Direct

Tech Support

Visit our tech support library at Help & Advice