An ammeter is at rest when its needle is centered. It measures current flow and can be either negative or positive. Without an expensive shunt (which Catalina never employed) all of the alternator output has to flow through the ammeter on its way to the batteries

Use of an ammeter dictated a very long electrical path.

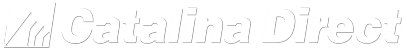

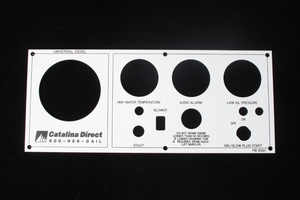

Before Universal Medalist Motors shipped their engine packages to boat builders all over the country, a final test of engine and panel operation was performed. This was accomplished with the engine still on a test bed by connecting an 8 pin plug on the back of the instrument panel to a similar plug directly on the engine. When the engine package was installed by the boat builder, the builder connected the two plugs by adding a suitable length Wiring Extension Harness depending upon their relative placement of engine and panel on that particular boat model.

This wiring scheme was originally created by Universal Medalist Motors who supplied the engine package to Catalina Yachts. The design caused multiple problems for Catalina owners over the years.

By the time power reached the batteries, the total run of the charging circuit was well over 35'. This long run of small #10 wire meant there was a significant voltage drop between the alternator and the batteries. The very small electrical contacts inside the plugs at each end of the Extension Harness create a high resistance, heating the plugs. The energy from the alternator must pass through the plugs four times, twice from the alternator to the engine panel and twice more on the way from the panel to the batteries, with a voltage drop occuring at every pass through a plug. As a result, when power eventually reached the batteries, the voltage was significantly less than the 14.2 volts required for a full battery charge. The batteries never fully charged, resulting in more frequent charging when at anchor.

Due to inadequate charging, batteries were often at less than a full charge when left at the slip resulting in reduced battery life.

A season or two in a marine environment also causes corrosion to the plug connections. An evening and overnight at anchor leaves the batteries significantly discharged. The next morning, when charging, the alternator attempts to push its full capacity through the high resistance connections at the plugs. This heats the plugs significantly and is a potential danger.

This is how it happens

We spent a long weekend aboard a Catalina 34. Anchoring in several SF Bay anchorages. We had a great time. At one anchorage we played cards late into the night. By morning, after having the anchor light on all night, the house batteries were pretty low. The boat was equipped with an engine battery plus two group 27 house batteries.

After coffee and breakfast, we fired up the engine on the start battery. After motoring a bit at cruising speed, I switched to the house bank to top them up. It didn't take long to notice a bit of smoke coming out of the engine compartment. I soon located the source; an eight pin plug that had melted so much it looked like a Dali painting.

To reduce electrical flow, I switched back to the single engine battery and throttled back the engine. By the time the sails were hoisted, the reduction of energy flowing through the plugs had let them cool enough they quit smoking.

Why the smoke? With the house bank at a low state of charge and while running at cruising speed, the alternator was trying to push nearly its full output through that long, small wire and through the high resistance plugs. If larger batteries or a higher output alternator had been aboard, all of the above problems would have been even worse.