Swear words flew across the room and my tools weren't far behind. One hour into what I thought would be a ten minute gooseneck replacement project and I was at my wits' end. The screws wouldn't budge and I was still a long way from even starting to remove the gooseneck casting. Galvanic corrosion had gotten the best of my normally calm demeanor. I vowed to not let this happen to me again.

What is galvanic corrosion?

Galvanic corrosion occurs whenever two metals with different electric potentials are in contact with each other in the presence of an electrolyte. Famed engineer Gustave Eiffel was well aware of the problem even in the late 1800's when he engineered the structure of the Statue of Liberty. We know this because he attempted to isolate the outer copper skin of the statue from the internal iron structure that he designed to support it. He used asbestos cloth soaked in shellac as an insulator between the dissimilar metals. Although well before modern material engineering breakthroughs, Eiffel’s solution initially acted as an effective barrier to prevent corrosion. Unfortunately, over time, the shellac broke down, the asbestos cloth wicked up salt water, the perfect electrolyte, enabling and even accelerating the galvanic corrosion. Modern engineers found a more effective solution to Lady Liberty's problem. They used PTFE (Teflon is the most common PTFE) polymer resin tape to isolate the different metals. This new type of barrier proved to be nearly impervious to corrosion.

When installing stainless steel fasteners into an aluminum spar, use the included brush to work the PTFE paste into the threads of the fastener and the tapped threads in the hole. Note: I have even applied paste to the countersink to prevent corrosion at the screw head.

How does this relate to my project?

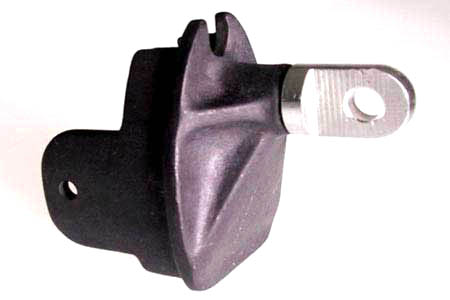

The screws are stainless steel and both the boom and the gooseneck are aluminum. In addition, the boom is extruded, while the gooseneck is cast. These different materials, manufacturing and finishing processes result in differences in electrical potential between the parts. This makes them prone to corrosion.

To remedy this, I needed a barrier to insulate the dissimilar metals from each other, to serve the same purpose as the PTFE barrier now used to protect the Statue of Liberty. However, the applications on my boat called for something different than tape. A different form factor was necessary.

I found my solution in a product called MareLube Tef. It is a PTFE barrier in the form of a light paste. It was designed specifically for high load/extreme pressure, anti-corrosion, anti-seize, and bi-metal barrier applications. It is a completely waterproof, tenacious, synthetic grease containing 45% PTFE sub-micron size powder. It doesn't wash away in fresh or salt water or detergents.

After we first published this Tech Article a customer responded with a reminder about a non-dissimilar metals use for Marelube. When stainless fasteners are threaded into a stainless fixture or nut there is potential for galling. Galling is when the metal of the male and female threads stick together and ball up in a way that makes it impossible to further tighten or loosen the fastener. The lubricating properties of Marelube help eliminate this potentially serious problem. Another hint: don't use power tools to install stainless into stainless. Go slow. Even the small amount of heat developed by the speed of a power tool increases the likelihood of galling.

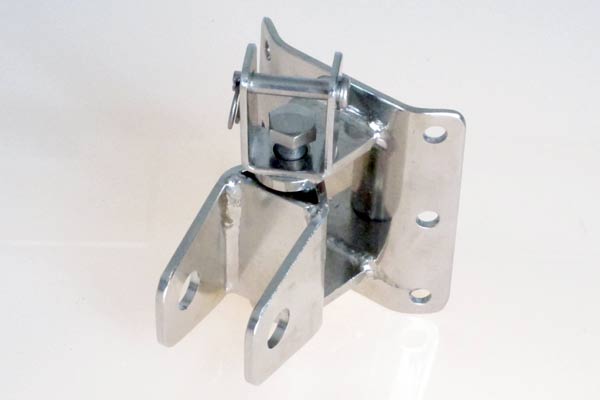

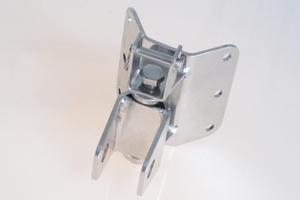

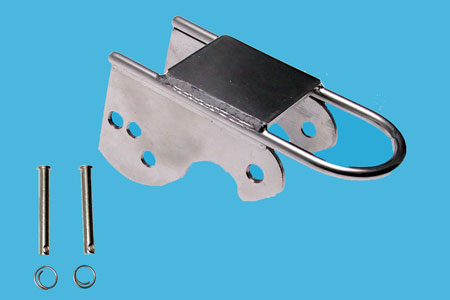

For hardware that includes a broad area where two different metals are in contact, use a PTFE film as an insulating barrier to prevent galvanic corrosion. I use a self adhesive version to hold it in place during installation.

What do I do when I mount a stainless plate on an aluminum spar?

When a stainless steel part is installed onto an aluminum spar, we must insulate the two dissimilar metals from each other. Just as was done during the restoration of the Statue of Liberty, you can install a PTFE insulator between the fitting and the spar. It is a good idea to have a couple of sheets of this film in your tool kit, available for future projects.

As indicated by the arrow, a thick, black dielectric film is applied anywhere the stainless steel spreader brackets will be in contact with the side of the aluminum mast.

An example of an area that demands protection by diaelectric film

When water, mixed with a bit of salt or contaminants from pollution lives between the stainless plate and aluminum spar, it is a perfect environment that promotes galvanic corrosion.

These stainless steel clevis pins were completely seized to the masthead truck casting. Applying the PTFE paste whenever re-installing the masthead clevis pins will prevent corrosion for years.

Corrosion can occur anywhere where stainless and aluminum are in contact

Looking back, I now know that Marelube should be applied anytime I disassemble then reassemble any metal-on-metal parts (including screws, clevis pins, etc). Even similar metals need to be protected. For example, mounting an aluminum casting to an aluminum extrusion should include Marelube. Though both parts are made from aluminum, the specific alloys are different and thus the two pieces have a different electrical potential, making them susceptible to galvanic corrosion.

A good example is this close-up photo of a Catalina 27 masthead. The clevis pins have welded themselves into place due to galvanic corrosion. The bond was so tight, that even after great effort was made to separate them, the casting broke before the pins would release. Taking a few extra seconds to apply anti-corrosion paste would have avoided several hours of effort and saved this masthead casting from failure.

In my case, it also would have prevented my tools flying across the room, and swear words streaming out of my mouth. My situation was a perfect illustration of why it's important to use the proper protectants and lubricants to save time and headache later.

I wanted to share this experience with you in the hopes that it might allow you to spend more time on the water, and less time wrestling with your gooseneck casting. I hope you found it useful!

Catalina Direct

Tech Support