I received a call from a concerned customer recently with a harrowing tale. I asked him to e-mail me the details and include a photograph that I might share with other Catalina sailors. Lessons learned from his experience with his 1988 Catalina 30 could be relevant whether you own a C-22 or a C-470.

Learn about another type or corrosion, Galvanic Corrosion, here.

A Harrowing Tale

"Last Sunday we sailed with a reefed main in about 15+ knot winds when all of a sudden the windward (starboard) chain plate for the upper shroud broke.

We managed to get the sails down and saved the mast. I ordered new chain plates from Catalina Direct, but I am concerned that this might reoccur in future... There is some surface rust on the part but the breakage almost looks like a result of electrolysis. To my knowledge, the boat was never hit by lightning and as you know the mast is grounded via the starboard side upper shroud.

I am attaching a picture. I did not clean the chain plate up so you can see the condition (the port side is ok), Please note how shredded the breakage is. Any comment you have would be appreciated. At this point I don’t know if I should warn the other owners of Catalina 30’ in my club (one was hit by lightning) or is this just an isolated case?

Thank you

Raimund Haunholter

Cape Coral, Florida"

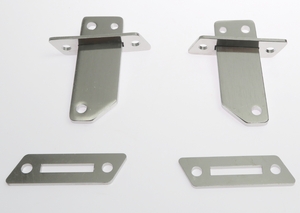

A typical case of crevice corrosion on a Catalina 30 chainplate. The corrosion at 'A' will not be visible when the part is installed. However, upon close inspection, signs of corrosion are visible at 'B'. The entire part should be bright silver like at surface 'C'.

A typical case of crevice corrosion

The failure of the upper shroud chainplate is a classic case of crevice corrosion. The "crevice" in this case is the small space surrounding the chainplate, between the stainless plate and the sealant, intended to protect the boat from water intrusion.

A few notes about the properties of metals might be helpful... Platinum, palladium, and gold do not corrode. Every other metal known to man does. Stainless steel becomes rust resistant with the addition of chromium. When chromium in the alloy is exposed to oxygen, a thin layer of chromium oxide forms. This ultra thin oxide layer is what protects the stainless. More chromium in the stainless provides better protection. This is why Catalina Direct uses type 316 stainless steel with higher chromium content for all of our standing rigging wire.

However, under the wrong conditions, any stainless steel will corrode. Airborne pollutants as well as chlorides in salt water attack the oxide layer. When stainless steel is kept clean, the oxide layer forms faster than the chlorides can attack it. But, if dirt and pollutants from the air and/or salt is left on the stainless, or if the surface of the stainless is deprived of oxygen, the oxide layer degrades faster than it can re-form. Once it breaks through the oxide layer, the chlorine attacks the metal itself. It quickly begins to damage the integrity of the hardware or fasteners as you can see in the photo.

The upper shroud chainplate can be an ideal environment for crevice corrosion where it passes through the deck. Often the chainplate is attached to a bulkhead and passes through the deck. When loaded and unloaded each time you tack, the chainplate moves ever so slightly relative to the deck it is passing through. This small motion breaks down the bond between the sealant and the chainplate. Now, salt water, with it's chloride content, not only enters the crevice between the plate and the sealant, but it is held there in an oxygen starved environment.

John C from Sunshine Acres, Queensland, Australia reports "The one that is broken had only finger tension on it and it came off in my hand. (No wrenches were used on it at all). So glad I didn't risk it and go for a sail"

An example of crevice corrosion on smaller boats

Small Crevice corrosion is also a problem on early Catalinas that used a simple, single eyebolt through the deck for the lower shroud chainplates. There was no provision made to prevent them from rotating in the hole. When adjusting the turnbuckle or, on trailerable boats, stepping or unstepping the mast, it was easy to accidentally rotate the eyebolt. Any slight rotation broke the seal and provided an ideal location for crevice corrosion to take place.

Any stainless hardware or fasteners penetrating the deck can be susceptible to crevice corrosion. Typically it is the larger flat surfaces of the bigger boat chainplates, but as you can see above, it can occur just as easily on threaded fasteners. Although less likely to flex or rotate as much as the early chainplate eyebolts, stanchion fasteners will often develop leaks earlier than other deck hardware due to the higher loads exerted on them when the stanchions or lifelines are used. Remember that your stanchions and lifelines were not designed to be used to stop the boat when coming into the slip.

In addition to rigging degradation, your deck structure is also effected. Every Catalina deck has a marine plywood core to add stiffness to the structure. Water intrusion at any point where hardware penetrates the deck is introducing water into the plywood core. This creates an ideal environment where the spores that cause dry rot can thrive. In just a season or two dry rot can destroy the plywood layer and create a void in the deck structure.

The rust at the top of the chainplate, under the turnbuckle is just from contaminates sitting between the toggle and the chainplate. A regular washdown after each sail will help prevent this from occurring.

What can you do to prevent stainless steel crevice corrosion?

Rinse with fresh water every time you sail even if sailing in fresh water. If you don't sail as often as you would like, make a pact with an adjoining slip renter to hose down the other's boat every time you visit yours.

Check both on deck and inside the cabin for any sign that the seal has been compromised. Be sure to use a flashlight inside the boat to check for the slightest sign of a leak. Is there anything but shiny stainless? Is there the slightest patina of rust on any of the hardware? Is there any indication of water having been on the adjacent wood? You can see in the photo the patina of rust on the top of the horizontal plate. This is a clear indication that the chainplate had been leaking. There is no small leak. Any leak at all is dangerous to your rig and the integrity of your deck.

Improved chainplate cover plates for the Catalina 34 and Catalina 36. The cover plate includes a vertical component that provides for more sealant and a greater area for the sealant to bond to the chainplate. This was not a feature of the original design. Current Catalinas incorporate an even newer chainplate design that installs from above deck which helps to eliminate leaks and possible crevice corrosion.

Is it time for action?

If there is any indication water has gotten through the seal at deck level the answer is an emphatic yes! Remove the entire chainplate or fastener and check for crevice corrosion that might be hidden within the thickness of the deck. Undetected it could cause the loss of your entire rig. Carefully clean the metal thoroughly. Re-bed both the chainplate and cover plate and you're good for another season. If there is an option to upgrade to a newer design chainplate and or covers, you might consider upgrading while you have the assembly apart for inspection. Once crevice corrosion starts, it is more difficult to prevent it from continuing. If there is any doubt about the integrity of the part, it's time to replace it.

Catalina Direct

Tech Support